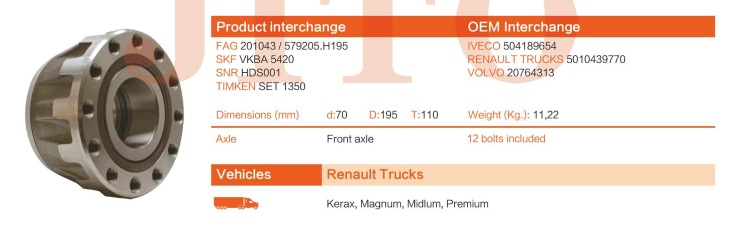

201043/579205.H195/VKBA 5420/SET 1350/HDS001 Wheel End Module 70*195*110 JITO/OEM

|

MODEL |

201043/579205.H195/VKBA 5420/SET 1350/HDS001 |

|

Dimension (mm) |

70*195*110 |

|

Axle |

Front axle 12 bolts included |

|

Weight(Kg) |

11.22 |

|

Product interchange |

FAG: 201043/579205.H195 SKF: VKBA 5420 SNR:HDS001 TIMKEN:SET 1350 |

|

OEM Interchange |

IVECO 504189654RENAULT TRUCKS 5010439770VOLVO 20764313 |

|

Vehicle |

RENAULT TRUCKS: Kerax,Magnum,Midlum,Premium |

|

Material |

GCr15 |

Advantages:

- As a rolling bearing, it has the characteristics of small starting friction coefficient, low power consumption, high mechanical efficiency and easy starting; its international standards and specifications are unified, easy to obtain interchangeability, easy to install and disassemble, and convenient maintenance; easy lubrication, low lubricant consumption; generally can withstand radial and axial loads at the same time; can be easily used under high or low temperature conditions; the bearing rigidity can also be improved by applying preload.

Maintenance points:

- Regular cleaning: When the bearing runs for a certain period of time (such as 2500-3000 hours) or when impurities such as sand and soil are found, or the lubricating oil deteriorates, it needs to be cleaned. Gasoline or kerosene can be used, first rough cleaning and then fine cleaning. Do not rotate the bearing during cleaning. After cleaning, wipe it dry with a clean cloth. Avoid wiping with cotton yarn to prevent fluff from falling in.

- Lubrication maintenance: Choose a suitable lubrication method according to the usage, such as grease lubrication or oil lubrication. Grease lubrication can be directly filled with grease to cover all roller surfaces; oil lubrication requires oil to be applied to the roller surface. Pay attention to regularly check the lubricant status, replenish or replace the lubricant in time to reduce internal friction and wear of the bearing and extend fatigue life.

- Precautions for installation and disassembly: During installation, ensure that the bearing and related parts are clean, check the size and finishing of the parts, and install them in the correct way. For example, the inner ring usually adopts interference fit, which can be pressed in or hot-fitted by a press. During disassembly, keep the used lubricant, damaged bearings, etc. to analyze the cause of the abnormality.

- Operation status monitoring: Pay attention to monitoring the operating status of the bearing during daily use, including rotation sound, vibration, temperature, etc. If any abnormality is found, such as increased noise, increased vibration, or excessive temperature, the machine should be stopped and checked in time to determine whether the bearing is faulty so that it can be dealt with in time.

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top