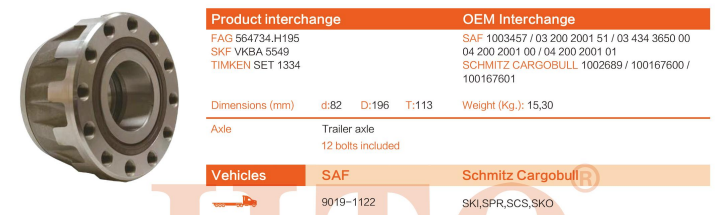

564734.H195/VKBA 5549/SET 1334 Wheel End Module 82*196*113 JITO/OEM

|

MODEL |

564734.H195/VKBA 5549/SET 1334 |

|

Dimension (mm) |

82*196*113 |

|

Axle |

Trailer axle 12 bolts included |

|

Weight(Kg) |

15.3 |

|

Product interchange |

FAG: 564734.H195 SKF: VKBA 5549 TIMKEN:SET 1334 |

|

OEM Interchange |

SAF 1003457/03200200151/0343436500004200200100/04200200101

SCHMITZ CARGOBULL 1002689/1001676001100167601 |

|

Vehicle |

SAF:9019-1122

Schmitz Cargobull:SKI,SPR,SCS,SKO |

|

Material |

GCr15 |

Advantages:

- Strong load-bearing capacity: As a truck wheel hub bearing, it can bear the weight of the vehicle and various loads generated during driving, including radial loads and axial loads, and can adapt to heavy-load conditions.

- Easy installation: The wheel hub bearing unit integrates multiple components into one. Compared with the traditional combination of multiple separate bearings, the installation process is simpler and can reduce installation time and workload.

- Maintenance-free or easy maintenance: Some wheel hub bearing units are pre-adjusted, greased and sealed, and have maintenance-free performance, reducing maintenance costs and downtime during use.

- High rotation accuracy: It can provide precise guidance for the rotation of the wheel hub, ensure the smooth rotation of the wheel, and help improve the driving performance and safety of the vehicle.

Maintenance:

- Regular inspection: Regularly monitor the operating status of the bearing, including listening to the rotation sound, detecting vibration and temperature, checking the status of the lubricant, etc. If abnormal sound, excessive vibration or high temperature is found, the machine should be stopped for inspection in time.

- Cleaning the bearing: When signs of failure of the bearing, impurities inside or deterioration of the lubricating oil are found, the bearing needs to be cleaned. You can first use a brush or cloth dipped in gasoline or kerosene to clean it, wash it at least twice, and then use gasoline to rinse off the kerosene residue to prevent rust. Do not turn the bearing when cleaning. After cleaning, wipe it dry with a clean cloth. Do not wipe it with cotton yarn to prevent fluff from falling in.

- Lubrication and maintenance: Regularly replenish or replace lubricants according to usage. Grease-lubricated bearings can be used directly if they are unopened. If they have been used, clean them and add pure grease as required; oil-lubricated bearings need to be cleaned and refilled with lubricating oil if necessary before installation.

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top