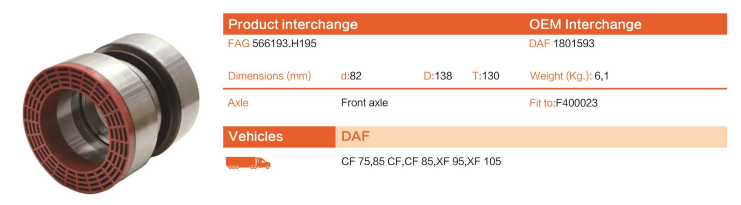

566193.H195 Hub Bearing for Commercial Vehicle 82*138*130 JITO/OEM

|

MODEL |

566193.H195 |

|

Dimension (mm) |

82*138*130 |

|

Axle |

Front axle |

|

Weight(Kg) |

6.1 |

|

Cage |

Carbon steel |

|

Product interchange |

FAG: 566193.H195 |

|

OEM Interchange |

DAF: 1801593 |

|

Fit to |

F 400023 |

|

Vehicle |

DAF: CF 75,85 CF,CF 85,XF 95,XF 105 |

|

Material |

GCr15 |

Advantages

- Strong load-bearing capacity:It can withstand the large radial and axial loads generated by the truck when running at full load, ensure the stable support of the wheel hub, and reduce the deformation and wear of the bearing.

- High reliability: After strict quality control and testing, it has high reliability and stability, can maintain good performance in long-term use, reduce the probability of failure, and reduce maintenance costs and downtime.

- Good sealing: The effective sealing structure can prevent the invasion of external impurities, protect the rolling elements and raceways inside the bearing, and extend the service life of the bearing.

- Easy installation: Designed as a unitized structure, it is easy to install and disassemble, improves maintenance efficiency, and reduces installation difficulty and cost.

Maintenance

- Regular inspection: Regularly check the working status of the bearing, including temperature, noise, vibration, etc., and promptly detect and deal with abnormal conditions. If the bearing temperature is found to be too high, there is abnormal noise or increased vibration, it may indicate that the bearing is worn, insufficient lubrication or other faults, and further inspection and repair are required.

- Lubrication and maintenance: Lubricate according to the prescribed cycle and requirements, select appropriate grease, ensure that the rolling elements and raceways inside the bearing are well lubricated, and reduce friction and wear. Different working environments and working conditions may require the use of greases with different properties. For example, high-temperature resistant greases are required in high-temperature environments.

- Cleaning and protection: Keep the bearings and their surroundings clean to prevent dust, dirt and other impurities from entering the bearings. During vehicle driving, the wheel hub is easily contaminated with dust and dirt. Regular cleaning can prevent these impurities from damaging the bearings. At the same time, check whether the seals are intact. If damaged, replace them in time to ensure the sealing of the bearings.

- Tightening inspection: Check whether the mounting bolts and nuts of the bearings are loose to ensure that the bearings are firmly installed. Loose mounting bolts may cause the bearings to move or vibrate during operation, accelerating the wear and damage of the bearings.

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top