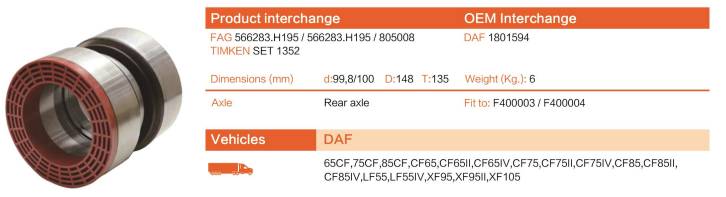

566283.H195/805008/SET 1352 Hub Bearing for Commercial Vehicle JITO/OEM 100*148*135

|

MODEL |

566283.H195/805008/SET 1352 |

|

Dimension (mm) |

100*148*135 |

|

Axle |

Rear axle |

|

Weight(Kg) |

6 |

|

Category |

Tapered Roller Bearing |

|

Cage |

Carbon steel |

|

Product interchange |

FAG: 566283.H195/805008TIMKEN: SET 1352 |

|

OEM Interchange |

DAF: 1801594 |

|

Fit to |

F 400003/F 400004 |

|

Vehicle |

DAF: 65CF,75CF,85CF,CF65,CF65II,CF65IV,CF75,CF75II,CF75IV,CF85,CF85II,CF85IV,LF55,LF55IV,XF95,XF95II,XF105 |

|

Material |

GCr15 |

Maintenance

- Lubrication: The appropriate grease must be selected according to the working conditions. Improper lubrication is the main cause of premature bearing failure. The filling amount should be 30% to 60% of the volume of the bearing and the bearing box.

- Installation environment: It needs to be installed in a dry and clean environment. Before installation, carefully check the mating surfaces of the shaft and the housing, clean them with gasoline or kerosene and dry them. During installation, the maximum inclination angle between the axis and the seat hole should not exceed 2′, and equal pressure should be applied to the circumference of the end face of the ring. When the interference is large, an oil bath or induction heating can be used for installation.

- Use inspection: Avoid strong impact during use and pay attention to rust prevention. Under normal working load, high temperature resistant lubricant and full lubrication, it can work at an ambient temperature of – 30°C to + 150°C. The operating speed should not exceed 30% to 50% of the limit speed. It is recommended to use 20% of the limit speed as the normal working speed. At the same time, it is necessary to measure the internal clearance regularly to ensure that the bearing obtains the appropriate clearance or preload, and identify the operating condition of the bearing by hearing and other means.

Application:

- Suitable for precision machinery. Judging from its related models as automobile wheel hub bearings, this bearing may also be used in automobile wheel hubs and other parts to withstand radial and axial loads during vehicle driving.

Advantages

- High load-bearing capacity: The structural characteristics of tapered roller bearings enable them to withstand large combined radial and axial loads, and are suitable for working conditions with large loads.

- Separability: Tapered roller bearings are usually separable. For example, the inner ring of a single-row tapered roller bearing with a roller and cage assembly can be installed separately from the outer ring, which is conducive to installation, disassembly and maintenance inspection procedures.

- Good interchangeability: Bearing components of the same size are interchangeable, which is convenient for maintenance and replacement of components

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top