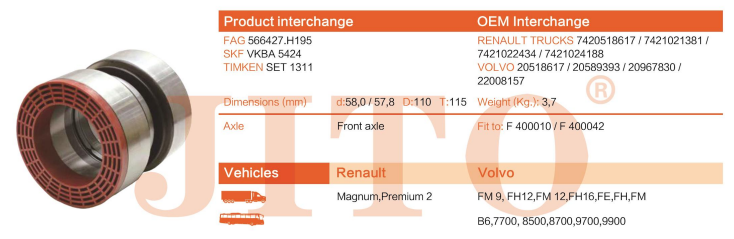

566427.H195/VKBA 5424/SET 1311 Hub Bearing for Commercial Vehicle JITO/OEM 58*110*115

|

MODEL |

566427.H195/VKBA 5424/SET 1311/BZ 2273 |

|

Dimension (mm) |

58*110*115 |

|

Axle |

Front axle |

|

Weight(Kg) |

3.7 |

|

Rolling element type |

Roller bearing |

|

Number of rows |

Double row |

|

Load direction |

Axial and radial |

|

Product interchange |

FAG: 566427.H195SKF: VKBA 5424TIMKEN: SET 1311 |

|

OEM Interchange |

RENAULT TRUCKS 7420518617/7421021381/7421022434/7421024188VOLVO 20518617/20589393/20967830/22008157 |

|

Fit to |

F 400010/F 400042 |

|

Vehicle |

Renault: Magnum,Premium 2Volvo: FM9,FH12,FM 12,FH16,FE,FH,FMB6,7700,8500,8700,9700,9900 |

|

Material |

GCr15 |

Advantages:

- High load-bearing capacity: The double-row roller structure enables it to withstand large axial and radial loads. It is suitable for the wheel hub of heavy vehicles such as trucks. It can support the weight of the vehicle and withstand various forces during driving.

- Good reliability: It is made of high-quality bearing steel, which has been precisely processed and heat-treated. It has high strength and wear resistance. It can maintain stable performance under harsh working conditions, reduce the probability of failure, and improve the reliability of vehicle operation.

- High precision: It can ensure the rotation accuracy of the wheel hub, make the wheel more stable during rotation, reduce vibration and noise, and improve driving comfort.

Application:

- Mainly used in the wheel hub of heavy trucks of brands such as Renault and Volvo. It is used to support the wheels so that they can rotate smoothly and withstand various loads such as vertical force, driving force, braking force and lateral force generated by the vehicle during driving. At the same time, it can ensure the rotation accuracy and stability of the wheels and ensure the safe driving of the vehicle.

Maintenance:

- Regular cleaning: Clean the bearings regularly with kerosene or gasoline to remove oil, dust and impurities on the surface to reduce wear and prevent corrosion.

- Check wear: Carefully observe the inner and outer raceways, rolling elements and cages of the bearings to check for cracks, peeling, wear, pitting and other damage phenomena, measure the clearance between the inner diameter of the bearing and the journal, and if the clearance is greater than 0.10mm, the bearing needs to be replaced in time.

- Lubrication and maintenance: Completely replace the lubricating oil or grease at least once every six months, select extreme pressure lithium-based grease with good heat resistance and extreme pressure, and apply it evenly to the bearing to ensure that the bearing is well lubricated and reduce friction and wear.

- Installation and adjustment: Use professional tools during installation, tighten the nut to the specified torque, rotate the wheel hub after installation to ensure that the bearing and seat ring fit correctly, and check the tightness of the bearing to ensure that the wheel can rotate freely and no axial clearance can be felt.

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top