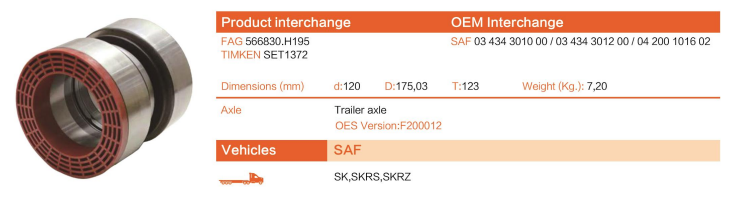

566830.H195/SET 1372/803904 Hub Bearing for Commercial Vehicle 120*175.03*123

|

MODEL |

566830.H195/SET 1372/803904 |

|

Dimension (mm) |

120*175.03*123 |

|

Axle |

Trailer axle |

|

Weight(Kg) |

7.2 |

|

Product interchange |

FAG: 566830.H195TIMKEN: SET 1372 |

|

OES Version |

F 200012 |

|

OEM Interchange |

SAF: 03434301000/03434301200/04200101602 |

|

Vehicle |

SAF:SK,SKRS,SKRZ |

|

Material |

GCr15 |

Structural features

- Double-row tapered roller structure: It consists of an inner ring, an outer ring, two rows of tapered rollers and a cage. The tapered surface of the tapered roller is at a certain angle to the axis of the bearing. This structure enables the bearing to withstand combined radial and axial loads, and the two rows of rollers can share the load and improve the load-bearing capacity.

- J steel plate stamping cage: The cage is stamped from J steel plate, which has good strength and toughness. It can effectively maintain the uniform distribution of tapered rollers, guide the rolling of rollers, reduce friction and collision between rollers, and also help to evenly distribute lubricating oil and improve lubrication effect.

- Straight raceway: The raceway is straight, and the contact line with the tapered roller is a straight line, which can evenly distribute the load on the roller and raceway, reduce local stress concentration, and improve the bearing’s load capacity and service life.

Maintenance points

- Regular lubrication: Regularly replace the grease of the wheel hub bearing according to the recommendations of the vehicle manufacturer. Generally speaking, after a car has traveled a certain mileage (such as 20,000-30,000 kilometers) or has been used for a certain period of time (such as 1-2 years), the grease should be checked and replenished or replaced. Choose high-quality grease suitable for high temperature and high speed conditions to ensure good lubrication.

- Check the seal: During each maintenance, carefully check the sealing device of the bearing, such as oil seals, dust covers, etc., to ensure that they are intact, and can effectively prevent dust, moisture and impurities from entering the bearing, and avoid these pollutants from causing bearing wear, corrosion and grease deterioration.

- Monitor temperature and noise: During the driving of the vehicle, pay attention to whether the temperature of the wheel hub increases abnormally, and whether there is any abnormal noise. If the temperature is too high or there is noise, it may indicate that there is a fault in the bearing, such as insufficient lubrication, roller wear, excessive bearing clearance, etc., and the vehicle should be stopped for inspection and repair in time.

- Avoid overloading: Avoid overloading the vehicle and prevent the wheel hub bearing from being subjected to excessive load, so as not to shorten the service life of the bearing or even cause bearing damage.

Application

- Mainly used in the wheel hub of automobiles to support the rotation of wheels and bear the impact loads from the vehicle’s own weight and uneven road surface as well as various forces during the driving process of the vehicle, such as driving force, braking force, lateral force, etc., to ensure that the wheels can rotate steadily and smoothly, and to ensure the driving performance and safety of the vehicle.

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top