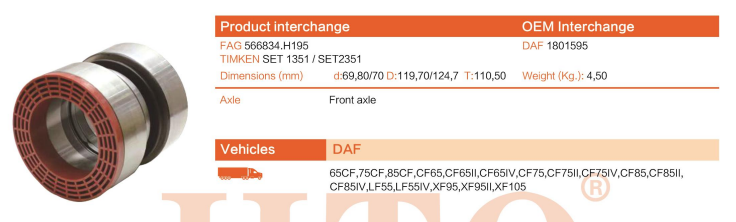

566834.H195/SET 1351/SET 2351 Hub Bearing for Commercial Vehicle 70*124.7*110.5 JITO/OEM

|

MODEL |

566834.H195/ SET 1351/SET 2351 |

|

Dimension (mm) |

70*124.7*110.5 |

|

Axle |

Front axle |

|

Weight(Kg) |

4.5 |

|

Product interchange |

FAG: 566834.H195TIMKEN: SET 1351/SET 2351 |

|

OEM Interchange |

DAF: 1801595 |

|

Vehicle |

DAF:65CF,75CF,85CF,CF65,CF65II,CF65IV,CF75,CF75II,CF75IV,CF85,CF851I,CF85IV,LF55,LF55IV,XF95,XF951I,XF105 |

|

Material |

GCr15 |

| Advantage | Specific manifestations |

| Low friction loss | Adopt angular contact ball bearing design, friction coefficient ≤ 0.0015, reducing energy consumption by 30% compared with traditional tapered roller bearings |

| Long life and maintenance free | After the sealing technology is upgraded, the service life can reach 100,000 to 150,000 kilometers (traditional bearings are about 50,000 to 80,000 kilometers) |

| Integrated design | The third generation hub bearing unit (HBU) integrates ABS sensors, reducing installation procedures and failure rates |

| Strong impact resistance | Preload optimization design, can withstand instantaneous impact of more than 3000N during emergency braking |

| Light weight advantages | The weight of a single wheel bearing is 40% lighter than that of a cast iron bearing, improving fuel economy |

Structural analysis: Evolution from parts to units

Basic structural components

- Inner ring and outer ring: The inner ring is interference fit with the axle, and the outer ring is fixed to the wheel hub, both of which are annular raceway designs;

- Rolling element: double-row angular contact ball bearings (mainstream for passenger cars) or tapered rollers (commercial vehicles), 16 to 24 in number;

- Cage: stamped steel or nylon material, to prevent ball friction and collision, and maintain uniform distribution.

Modern unitized design (third generation HBU)

- Integrated structure: Integrate bearings, seals, and sensors (magnetoelectric or Hall type) into one;

- Typical case: For example, SKF’s Explorer series uses an integrated package of “bearing + electronic module” to directly output wheel speed signals.

Maintenance points: Key operations to extend life

Daily inspection

- Abnormal noise detection: If a “buzzing” sound occurs at a speed of more than 40km/h, it may be due to bearing wear (clearance > 0.15mm needs to be replaced);

- Temperature monitoring: Touch the wheel hub after driving. If the temperature is abnormally higher than other parts of the vehicle body, it may be insufficient lubrication or over-tight installation.

Lubrication and replacement

- Lubrication cycle: Traditional bearings are supplemented with lithium-based grease (NLGI grade 2) every 50,000 kilometers, and unitized bearings are maintenance-free for life;

Replacement precautions:

- Torque standard: Bolt tightening torque must be in accordance with the vehicle model manual (such as Volkswagen models are 120~150N・m);

- Anti-corrosion treatment: Apply anti-seize agent to the shaft head during installation to avoid rust.

Fault warning

- If the ABS fault light is on or the wheel speed data is abnormal, it may be due to the deflection of the sensor magnetic ring in the bearing (allowable error ≤0.2mm).

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top