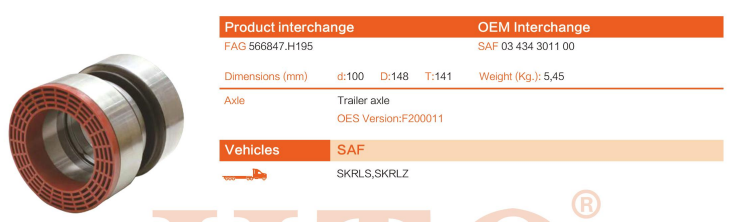

566847.H195 Hub Bearing for Commercial Vehicle 100*148*141 JITO/OEM

|

MODEL |

566847.H195 |

|

Dimension (mm) |

100*148*141 |

|

Axle |

Trailer axle |

|

OES Version |

F 200011 |

|

Weight(Kg) |

5.45 |

|

Product interchange |

FAG: 566847.H195 |

|

OEM Interchange |

SAF: 03434301100 |

|

Vehicle |

SAF:SKRLS, SKRLZ |

|

Material |

GCr15 |

Features and advantages:

- Strong load-bearing capacity: The tapered roller bearing structure enables it to efficiently bear radial and axial combined loads, and is suitable for working conditions where the wheel hub must bear both the radial force generated by the vehicle’s own weight and the axial force generated by brakes, etc.

- Adjustable clearance: If it is a single-row tapered roller bearing, the clearance can be flexibly adjusted during installation, and the bearing performance can be optimized according to the actual working conditions.

- Easy installation and maintenance: The separate structure makes installation and disassembly relatively easy, and is convenient for operations such as replacement of wheel hub bearings during vehicle maintenance.

- Good interchangeability: Standardized design, the inner and outer ring components of the same model have good global interchangeability, which is convenient for accessory procurement and replacement.

Application field:

- Mainly used in the automotive industry, specifically in the wheel hub of the car, used to support the wheel and ensure the rotation accuracy of the wheel, while bearing various loads during vehicle driving. In addition, bearings with similar structures and functions may also be used in some commercial vehicles such as heavy trucks and buses.

Maintenance points:

- Clearance adjustment: During installation, the clearance must be accurately set according to the bearing arrangement, span, shaft and seat materials, and actual working conditions (speed, load, vibration). Under high speed and heavy load conditions, the clearance reduction caused by temperature rise should be considered, and the initial clearance should be appropriately increased; in low speed or vibration situations, no clearance or pre-tightening installation can be adopted.

- Keep clean: Keep the bearing and working environment extremely clean to prevent tiny particles from invading the inside of the bearing to avoid aggravating wear and affecting the rotation accuracy.

- Standard operation: When installing and disassembling, special tools should be used to avoid impact that causes indentation, cracks or even breakage of the bearing.

- Anti-rust treatment: Keep hands clean or wear gloves during operation to prevent sweat from contacting the bearing and causing rust. If stored for a long time, appropriate anti-rust measures should be taken.

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top