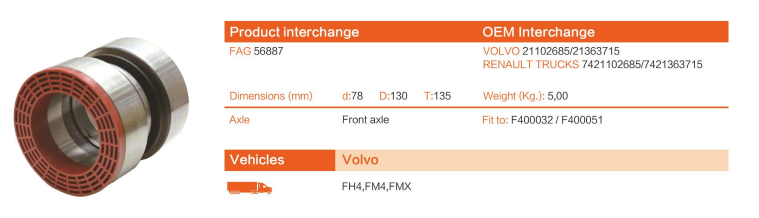

56887 Hub Bearing for Commercial Vehicle 78*130*135 JITO/OEM

|

MODEL |

56887 |

|

Dimension (mm) |

78*130*135 |

|

Axle |

Front axle |

|

Weight(Kg) |

5 |

|

Fit to |

F 400032/F 400051 |

|

Product interchange |

FAG: 56887 |

|

OEM Interchange |

VOLVO: 21102685/21363715RENAULT TRUCKS: 7421102685/7421363715 |

|

Vehicle |

VOLVO: FH4,FM4,FMX |

|

Material |

GCr15 |

Advantages

- High load-bearing capacity: Bearings are usually made of high-strength materials, and their design focuses on load-bearing performance. They can withstand large radial and axial loads, can operate stably under high-load conditions, and are suitable for heavy-duty equipment such as mining and metallurgy.

- High precision and high operating stability: It uses advanced production equipment and precision detection technology, with high bearing dimensional accuracy and surface finish, stable operation, which can reduce friction and wear during the operation of mechanical equipment and improve equipment operation efficiency.

- Long life: Its bearing material has excellent wear resistance and fatigue resistance, reasonable internal structure design, and strict quality control. Even under harsh conditions and long-term high-load operation, it can maintain stable performance and reduce equipment maintenance frequency and downtime.

- Good sealing and lubrication performance: It has an excellent sealing design that can effectively prevent dust and pollutants from entering and ensure the normal operation of the bearing. At the same time, it adopts advanced lubrication technology, and there are a variety of lubrication methods to choose from, which can meet the lubrication needs under different working conditions, reduce friction, and extend service life.

Maintenance

- Lubrication and maintenance:Bearings can usually be lubricated with oil or grease, which needs to be selected according to the working environment. In high temperature environments, oil lubrication may be more suitable; in closed spaces or low temperature environments, grease lubrication can better provide long-term lubrication. The lubrication status needs to be checked regularly and the lubricant needs to be replenished or replaced in time.

- Fault monitoring: The working status of the bearing can be monitored in real time through sensors, such as vibration, temperature and other parameters, to detect potential faults in time, achieve predictive maintenance, and reduce the risk of equipment downtime. Because bearing vibration is very sensitive to damage, damage such as peeling and indentation will be reflected in vibration measurement.

- Installation and disassembly: During installation, attention should be paid to ensuring installation accuracy to avoid bearing damage or performance impact due to improper installation. Due to the high precision of FAG bearings, professional installation tools and methods may be required. Also be careful when disassembling to prevent damage to the bearing and related components.

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top