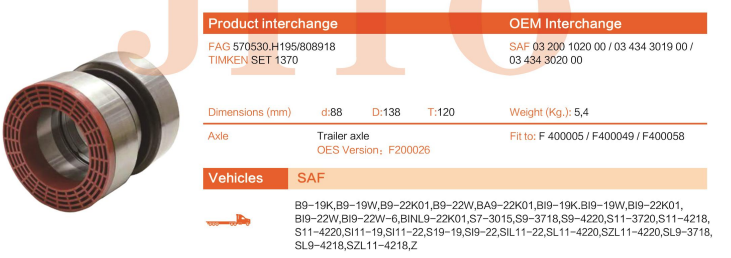

570530.H195/808918/SET 1370 Hub Bearing For Commercial Vehicle 88*138*120 JITO/OEM

|

MODEL |

570530.H195/808918/SET 1370 |

|

Dimension (mm) |

88*138*120 |

|

Axle |

Trailer axle |

|

Weight(Kg) |

5.4 |

|

Fit to |

F 400005/F 400049/F 400058 |

|

Product interchange |

FAG: 570530.H195/808918TIMKEN: SET 1370 |

|

OES Version |

F 200026 |

|

OEM Interchange |

SAF: 03200102000/03434301900/03434302000 |

|

Vehicle |

SAF:B9-19K,B9-19W,B9-22K01,B9-22W,BA9-22K01,BI9-19K.BI9-19W,BI9-22K01,BI9-22W,BI9-22W-6,BINL9-22K01,S7-3015,S9-3718,S9-4220,S11-3720,S11- 4218,S11-4220,SI11-19,S111-22,S19-19,SI9-22,SIL11-22,SL11-4220,SZL11-4220,SL9 SL9-4218,SZL11-4218,Z |

|

Material |

GCr15 |

Application:

- Mainly used in the wheel hub of heavy trucks, and also widely used in equipment that needs to withstand high loads and adapt to harsh working conditions in heavy industrial fields such as conveyors, mining, pulp and paper, and metallurgy.

Advantages

- Strong load-bearing capacity: The special design of the spherical roller bearing enables it to withstand large radial and axial loads, and adapt to the working requirements of heavy equipment such as heavy trucks.

- Self-aligning function: It can automatically adjust the angular deviation between the shaft and the bearing seat, effectively absorb vibration and impact, reduce the damage to the equipment caused by vibration, and extend the overall service life of the equipment.

- High reliability: High-quality materials and advanced manufacturing processes ensure the stability and reliability of the bearing during long-term operation, reduce the probability of failure, and improve the working efficiency of the equipment.

Maintenance

- Regular inspection: Regularly check the operating conditions of the bearings, including temperature, vibration, noise, etc., as well as the condition of the seals, and promptly identify and deal with problems.

- Cleaning and lubrication: Clean the bearings according to the prescribed cycle, remove impurities such as oil and dust, and replace or replenish grease to ensure good lubrication of the bearings.

- Correct installation and removal: When installing and removing bearings, special tools should be used and the correct method should be followed to avoid damage to the bearings.

Attributes

- Material: Generally made of bearing steel, it has high strength, high wear resistance and good toughness, and can withstand heavy loads and high speed working conditions.

- Size: Inner diameter is 88mm, outer diameter is 138mm, height is 120mm.

- Applicable models: SAF and other heavy truck models.

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top