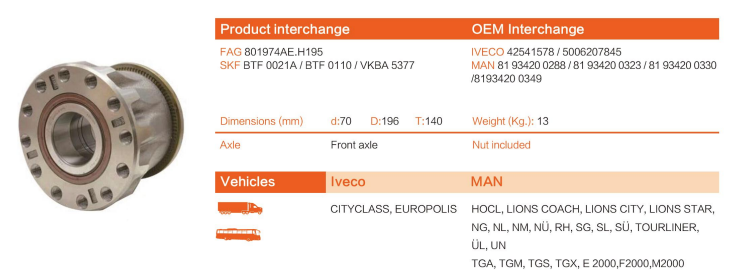

801974AE.H195/VKBA 5377/BTF0021A/BTF0110 Wheel End Module 70*196*140 JITO/OEM

|

MODEL |

801974AE.H195/VKBA 5377/BTF0021A/BTF0110 |

|

Dimension (mm) |

70*196*140 |

|

Axle |

Front axle Nut included |

|

Weight(Kg) |

13 |

|

Product interchange |

FAG: 801974AE.H195 SKF: VKBA 5377/BTF0021A/BTF0110 |

|

OEM Interchange |

IVECO 42541578/5006207845

MAN 81934200288/81934200323/81934200330/81934200349 |

|

Vehicle |

IVECO: CITYCLASS,EUROPOLIS

MAN:HOCL,LIONS COACH,LIONS CITY,LIONS STAR,NG, NL, NM, Nü, RH, SG, SL, Sü, TOURLINER,UL,UN TGA,TGM,TGS,TGX,E 2000,F2000,M2000 |

|

Material |

GCr15 |

Application:

- Mainly used in the automotive field, especially in MAN brand TGS, TGX, TGM, TGA, F2000, M2000, NL and other series of models, used as front wheel hub bearings.

Maintenance:

- Cleaning: When the bearing shows signs of failure, there are impurities inside or the lubricating oil deteriorates, or after running for 2500-3000 hours, it needs to be cleaned. First, use a brush or cloth dipped in gasoline or kerosene to clean it at least twice, and then wipe it dry with a clean cloth. Do not wipe it with cotton yarn to prevent fluff from falling in.

- Lubrication: The purpose of lubrication is to reduce friction and wear, extend fatigue life, and discharge friction heat. Lubrication methods are divided into grease lubrication and oil lubrication, which can be selected according to the conditions and purpose of use. If the bearing has been sealed with grease, it can be used directly without cleaning.

- Installation inspection: Before installation, clean the bearing and related parts, and check the size and finishing of the parts. After installation, check whether the bearing is running normally and supply lubricant as required.

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top