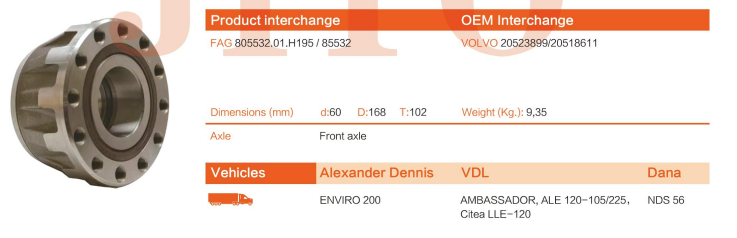

805532.01.H195/85532 Wheel End Module 60*168*102 JITO/OEM

|

MODEL |

805532.01.H195/85532 |

|

Dimension (mm) |

60*168*100 |

|

Axle |

Front axle |

|

Weight(Kg) |

9.35 |

|

Product interchange |

FAG: 805532.01.H195/85532 |

|

OEM Interchange |

VOLVO 20523899/20518611 |

|

Vehicle |

Alexander Dennis: ENVIRO200VDL:AMBASSADOR,ALE 120-105/225,Citea LLE-120

Dana: NDS 56 |

|

Material |

GCr15 |

Maintenance method:

- Regular inspection: Monitor the operating status of the bearing, including rotation sound, vibration, temperature, lubricant status, etc. If there are signs of bearing failure, impurities such as sand in the bearing, the lubricant begins to harden and deteriorate, or the bearing runs for 2500-3000 hours, maintenance should be carried out.

- Cleaning the bearing: First remove the old oil in the bearing, then use a brush or cloth dipped in gasoline or kerosene to clean the bearing, at least twice. Do not rotate the bearing during cleaning to prevent debris from being pressed into the bearing raceway. Bearings cleaned with kerosene should be cleaned with gasoline again to prevent rust. The cleaned bearings should be wiped dry with a clean wipe, and the bearings should not be touched by hand to prevent rust caused by sweat.

- Lubrication and maintenance: Regularly replenish or replace the lubricant according to the use of the bearing. For bearings with dust covers and lifetime lubrication, additional lubrication is generally not required, but if leakage occurs, corresponding measures must be taken.

Application properties:

- Deep groove ball bearings are widely used in precision instruments, low-noise motors, automobiles, motorcycles and general machinery. They mainly bear radial loads and can also bear a certain amount of axial loads. 805532.01.H195/85532 This specification of bearings, due to its larger size, may be more suitable for some large mechanical equipment or occasions with higher load-bearing capacity requirements, such as truck wheels.

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top