VKBA 5314 High Precision JITO/OEM Hub Bearings for Commercial Vehicles Front Axle 68/68.2*127/132*115

◎ Structural type

○ Traditional wheel hub bearing unit: simple structure, low manufacturing cost, strong maintainability, the longest market application time, accounting for about 80% of the total commercial vehicle wheel hub assembly. It consists of basic components such as inner ring, outer ring, rolling element and cage, usually grease lubrication. After the vehicle is running, the wheel end needs to be disassembled regularly for maintenance, such as cleaning the bearings and replacing grease, etc. The maintenance cost is high, and the preload needs to be adjusted during assembly, which has high requirements for the assembly process of the wheel hub assembly.

○ Grease-lubricated wheel hub bearing unit: It is a maintenance-free wheel hub bearing unit. It does not require maintenance during the use of the vehicle and can achieve a service life of more than 50×104 km. It simplifies the process of installing the wheel hub to the axle and removing it from the axle. The wheel hub bearing unit is assembled as a whole and does not need to adjust the clearance. It has high processing accuracy and high manufacturing cost, and is mainly used in high-end commercial buses.

○ Oil-lubricated wheel hub bearing unit: It is a low-maintenance wheel hub bearing unit. The oil volume and color of the oil need to be observed during the use of the vehicle. When replacing, there is no need to disassemble the wheel end. Just drain the oil through the drain plug and then add new oil. It also simplifies the process of installing the wheel hub to the axle. The overall assembly does not require the adjustment of the clearance. The processing accuracy and manufacturing cost are high, and it is mainly used in high-end commercial buses.

|

MODEL |

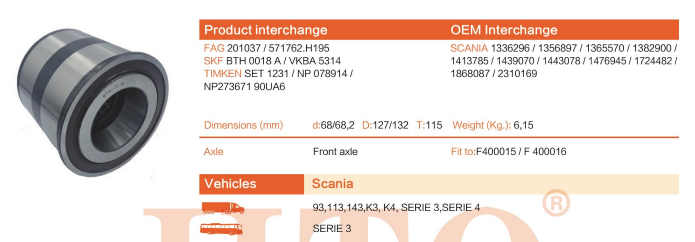

BTH 0018A/VKBA5314 |

|

Dimension (mm) |

68/68.2*127/132*115 |

|

Axle |

Front Axle |

|

Weight(Kg) |

6.15 |

|

Fit to |

F400015/F400016 |

|

Applicable models |

Scania 2-series 112h/280, Scania P, G, R, T-series p560, r560, DAF F1500 FA1500 DF, FD1500 DF, etc. |

|

Limit speed (grease lubrication) |

3200r/min |

|

Limit speed (oil lubrication) |

4300r/min |

◎ Working Principle

○ Rolling friction mechanism: Rolling elements (such as tapered rollers or steel balls) roll between the inner and outer raceways, converting sliding friction into rolling friction, significantly reducing the friction coefficient, which can generally be reduced to 0.001-0.005, while the friction coefficient of sliding bearings is usually 0.1-0.2, thereby improving rotation efficiency and reducing energy loss.

○ Load distribution: The double-row rolling elements are symmetrically arranged and can simultaneously bear radial loads, such as the vehicle’s own weight, and axial loads, such as the inertia force during braking. This reasonable load distribution method enables the hub bearing to maintain a stable working state under complex stress conditions.

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top