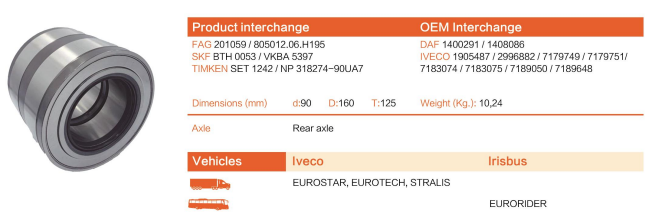

SET 1242/NP 318274-90UA7/BTH0053/VKBA5397 Hub Bearing for Commercial Vehicles 90*160*125

|

Category |

Double Row Tapered Roller Bearings |

|

MODEL |

BTH 0053/VKBA5397/SET1242/NP318274-90UA7 |

|

Dimension (mm) |

90*160*125 |

|

Axle |

Rear axle |

|

Weight(Kg) |

10.24 |

|

OEM Interchange |

DAF 1400291/1408086IVECO 1905487/2996882/7179749/7179751/7183074/7183075/718905017189648 |

|

Vehicle |

Iveco: EUROSTAR,EUROTECH,STRALISIrisbus: EURORIDER |

|

Material |

GCr15 |

Performance characteristics

- High load-bearing capacity: It can withstand large combined radial and axial loads and moment loads, mainly radial. It is suitable for parts such as automobile wheels that need to bear multiple loads at the same time. It can support the weight of the wheel and deal with the impact force caused by uneven road surfaces.

- Precisely guide rotation: As an automobile wheel hub bearing, it can accurately guide the rotation of the wheel hub to ensure the stability and accuracy of the wheel rotation, which helps to improve the vehicle’s handling performance and driving safety.

- Good rigidity: It can make the bearing deform less when bearing loads, maintain the position accuracy of the shaft, ensure stable operation of the equipment, and reduce vibration and noise caused by bearing deformation.

- No need to adjust the clearance on site: The clearance has been given according to user requirements at the factory, and the user does not need to adjust it during installation. It is easy to install and can ensure that the bearing has appropriate clearance under different working conditions to improve its performance and life.

Application fields

- Automotive industry: Mainly used in the wheel hub of commercial vehicles such as trucks, buses, and trucks, as wheel hub bearings to support the weight of the vehicle and ensure the smooth rotation of the wheels. At the same time, it can also withstand various forces generated during the driving process of the vehicle, such as radial force, axial force, etc. In addition, it is also used in some special vehicles, such as engineering vehicles and military vehicles. 3.

- Industrial machinery: It is also widely used in some industrial machinery that needs to withstand large loads, such as cranes, conveyors, reducers and other equipment transmission parts, used to support the rotating shaft, transmit power, and ensure the normal operation of the equipment.

Installation and maintenance

- Installation: During installation, it is necessary to keep the bearing and the installation part clean to prevent impurities from entering the bearing. At the same time, use appropriate installation tools and install according to the correct installation method to ensure that the bearing is installed in place to avoid installation deviations that cause bearing damage or abnormal operation. For example, when installing a wheel hub bearing, a special press machine is required to press the bearing into the wheel hub, and the installation accuracy and fit clearance of the bearing must be ensured.

- Lubrication: Correct lubrication is the key to ensuring the normal operation of the bearing. Generally speaking, BTH 0053 bearings can be lubricated with lithium-based grease or lubricating oil. Grease has good sealing and adhesion, and can form a protective film on the bearing surface to reduce wear and friction; lubricating oil has good heat dissipation performance and is suitable for high-speed rotating bearings. During use, grease or lubricating oil should be added or replaced regularly according to the working conditions and requirements of the bearing.

- Inspection and maintenance: Regularly inspect and maintain the bearings, promptly detect problems such as wear and damage of the bearings, and take appropriate measures to deal with them. The inspection content includes the temperature, vibration, noise, lubrication condition, etc. of the bearings. If the bearing temperature is too high, the vibration is too large, or there is abnormal noise, etc., it is necessary to stop the machine for inspection in time, find out the cause, and repair or replace the bearing.

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top