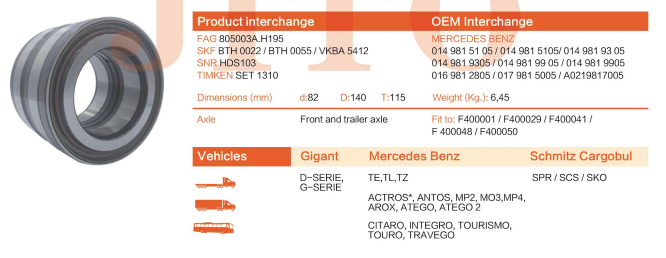

VKBA 5412/BTH 0022/BTH 0055 Wheel Hub Bearing for Commercial Vehicles 82*140*115 Front and Trailer Axle

|

MODEL |

BTH 0022/BTH 0055/VKBA5412 |

|

Dimension (mm) |

82/140/115 |

|

Axle |

Front and trailer axle |

|

Weight(Kg) |

6.45 |

|

Fit to |

F400001/F400029/F400041/F400048/F400050 |

|

Applicable models |

Gigant (D-SERIE, G-SERIE)Mercedes Benz(TE,TL,TZ, ACTROS*,ANTOS.MP2,MO3,MP4,AROX,ATEGO,ATEGO 2CITARO,INTEGRO,TOURISMO,TOURO,TRAVEGO)

Schmitz Cargobul(SPR,SCS,SKO) |

Principle

- Rolling friction mechanism: The tapered roller rolls between the inner and outer raceways, converting sliding friction into rolling friction. The friction coefficient can be reduced to 0.001 – 0.005, making the wheel rotate more smoothly and reducing energy loss.

- Load distribution: The double-row tapered rollers are symmetrically arranged, which can simultaneously bear the radial load and axial load generated during the vehicle’s driving process. The load is reasonably shared through the inner ring, outer ring and cage to ensure the smooth operation of the wheel and withstand large torque.

Maintenance

- Regular inspection: It is recommended to conduct an inspection every two months or 20,000 to 30,000 kilometers. The specific cycle is adjusted according to the vehicle’s usage. For vehicles that often carry heavy objects and drive on bad roads, the maintenance cycle should be shortened accordingly.

- Disassembly and cleaning: Stop the vehicle, set up the axle, ensure safety, remove the hub axle head decorative cover, dust cover, tire nut and tire, etc., and remove the hub with special tools. Scrape off the old grease in the bearing, journal and hub cavity, clean with a cleaning agent and wipe dry.

- Component inspection: Check the wheel hub bearing and bearing race. If cracks, fatigue peeling, loose bearing rollers or pitting on the bearing race are found, the bearing should be replaced. At the same time, check the fit between the inner diameter of the bearing and the journal. The fit clearance should be ≤0.10mm. If it exceeds the limit, the bearing needs to be replaced.

- Lubrication and installation: After confirming that the parts meet the requirements, apply grease to the inner bearing and put it into the wheel hub. When applying grease to the inner cavity of the bearing, the grease should be squeezed into the bearing until it emerges on the other side. A thin layer of grease should be applied to the wheel hub cavity and the shaft head cover to prevent rust. Install the wheel hub and outer bearing back to the journal, install the shaft head nut, tighten it according to the specified torque, turn the wheel hub left and right to check the installation, and finally install other components in sequence. It should be noted that the preload force of the wheel hub bearing should be controlled within the specified range, and the amount of grease applied should be moderate.

Application

- Load-carrying transport vehicles: widely used in trucks, large buses and other load-carrying transport vehicles, bearing the vehicle’s own weight and cargo weight, providing precise guidance for the rotation of the wheels, and ensuring the smooth driving of the vehicle under heavy load.

- Vehicles in harsh road conditions: Due to its high load-bearing capacity and reliability, it is also suitable for vehicles that often travel in harsh road conditions, such as engineering vehicles, mining vehicles, etc., and can adapt to complex road conditions and large impact loads.

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top