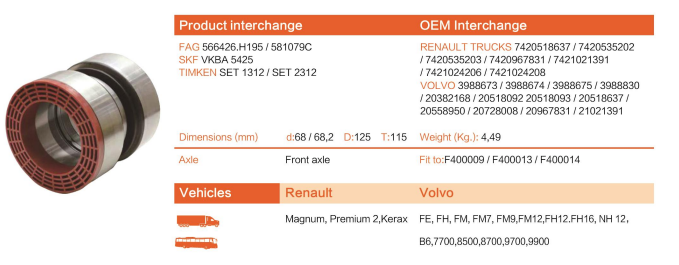

VKBA 5425/SET 1312/SET2312/566426.H195/581079C Hub Bearing for Commercial Vehicle JITO/OEM

|

MODEL |

VKBA 5425/SET 1312/SET2312/566426.H195/581079C |

|

Dimension (mm) |

68*125*115 |

|

Axle |

Front axle |

|

Weight(Kg) |

4.49 |

|

Product interchange |

FAG 566426.H195/581079CSKF VKBA 5425TIMKEN SET 1312/SET 2312 |

|

OEM Interchange |

RENAULT TRUCKS 7420518637/7420535202/7420535203/7420967831/7421021391/7421024206/7421024208VOLVO 3988673/3988674/3988675/3988830/20382168/2051809220518093/20518637120558950/20728008/20967831/21021391 |

|

Fit to |

F400009/F400013/F400014 |

|

Vehicle |

Renault:Magnum,Premium 2,KeraxVolvo:FE,FH,FM,FM7,FM9,FM12,FH12.FH16,NH 12,B6,7700,8500,8700,9700,9900 |

|

Material |

GCr15 |

Application:

- Applicable models: Mainly used in trucks of brands such as Volvo and Renault, suitable for the front axle, rear axle and hub parts of the front and rear wheels of the trucks.

Advantages:

- Pre-adjustment design: Pre-adjustment, lubrication and sealing have been carried out in the factory, which simplifies the installation process, reduces the workload and difficulty of on-site installation, and also helps to ensure the quality of installation.

- Good stability: It has the characteristics of temperature resistance, strong stability and wear resistance, and can withstand the large radial and axial loads generated by the truck during driving, adapt to complex road conditions and different driving conditions, and ensure the safety and reliability of vehicle operation.

- Low noise and low vibration: The low-beating design can reduce noise and vibration, help improve the comfort of the vehicle, and improve braking performance.

- Long life: High-quality materials, precise manufacturing processes, and good sealing and lubrication design help to extend the service life of the bearing, reduce the frequency of maintenance and replacement, and reduce the cost of use.

Maintenance:

- Regular inspection: Regularly check the working status of the bearing, including whether there is abnormal noise, vibration, heat, etc., as well as the tightness of the hub. If abnormalities are found, further inspection and repair should be carried out in time.

- Cleaning and lubrication: Although the bearing has been lubricated and sealed at the factory, the amount and quality of grease still need to be checked after the vehicle has traveled a certain mileage or has been used for a period of time, and the grease should be replenished or replaced if necessary. At the same time, the bearing surface and the surrounding environment should be kept clean to prevent dust, impurities, etc. from entering the bearing and affecting its performance and life.

- Installation and removal: When installing and removing bearings, special tools and correct methods should be used to avoid damage to the bearings. When installing, ensure that the bearings are installed in place and the matching accuracy meets the requirements; when disassembling, be careful to avoid damage to the inner ring, outer ring, rolling element, cage and other components of the bearing.

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top