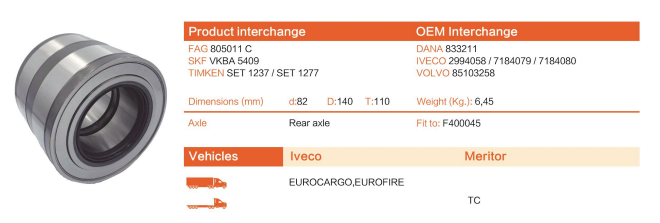

VKBA5409/SET1237/SET1277 Rear axle 82*140*110 Hub Bearing for Commercial Vehicle OEM/JITO

|

Category |

Double Row Tapered Roller Bearings |

|

MODEL |

VKBA5409/SET1237/SET1277 |

|

Dimension (mm) |

82*140*110 |

|

Axle |

Rear axle |

|

Weight(Kg) |

6.45 |

|

OEM Interchange |

DANA 833211IVECO 2994058/7184079/7184080VOLVO 85103258 |

|

Vehicle |

Iveco EUROCARGO,EUROFIREMeritor TC |

|

Structure |

Tapered roller structure |

|

Accuracy grade |

ABEC-1 |

|

Clearance |

C3 |

|

Material |

GCr15 |

Features and Advantages

- Strong load-bearing capacity: The structure of the tapered roller bearing enables it to withstand large radial and axial loads, which is suitable for the wheel hub of heavy-duty vehicles such as trucks, and can effectively support the weight of the vehicle and various forces generated during driving.

- Good durability: Made of high-quality chrome steel, it has high strength and hardness, excellent wear resistance, and can withstand long-term heavy loads and friction, extending the service life of the bearing and reducing maintenance and replacement costs.

- High reliability: The rubber seal design can effectively prevent dust, moisture and impurities from invading the inside of the bearing, protect the rolling elements and raceways of the bearing, ensure that the bearing can maintain good performance even in harsh working environments, and improve the reliability of the bearing.

- Smooth operation: The high-precision manufacturing process and ABEC-1 accuracy grade ensure the rotation accuracy of the bearing, making the bearing more stable during operation, reducing vibration and noise, and improving the comfort and stability of vehicle driving.

Structure

- Outer ring: fixedly connected to the truck’s steering knuckle or suspension bracket, plays a supporting and positioning role, bears the load from the outside of the vehicle, and transmits it to the rolling element.

- Inner ring: interference fit with the wheel hub or drive shaft, rotates with the wheel hub, provides a rolling track for the rolling element, and transmits the rotational motion of the wheel to the drive shaft.

- Rolling element: generally uses double-row tapered rollers. This design can bear radial and axial loads at the same time, and can maintain good rolling performance under high loads, reducing friction and wear.

- Cage: used to separate the rolling elements so that they are evenly distributed between the inner and outer rings, avoiding direct contact and friction between the rolling elements, while guiding the movement of the rolling elements to ensure the smooth operation of the bearing.

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top