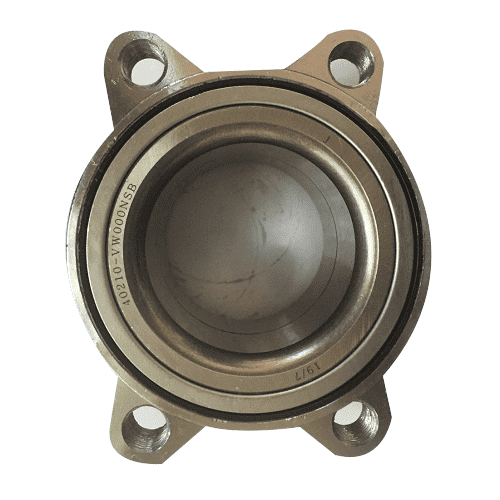

Automotive Wheel Hub Shaft Bearing 40210-VW000

*Specifications

|

40210-VW000 Bearing Detail |

|

| Item | Wheel bearing 40210-VW000 |

| other No. | 40210-VW000 |

| Bearing Type | Wheel Hub unit bearing |

| Material | GCr15 steel,carbon steel,stainless steel etc. |

| Precision | P0,P2,P5,P6,P4 |

| Clearance | C0,C2,C3,C4,C5 |

| Noise | V1,V2,V3 |

| Cage type | brass;steel plate,nylon,aluminium alloy etc. |

| Ball Bearings Feature | Long-life with high quality |

| Low-noise with strict controlling the quality of Ruben bearing | |

| High-load by the advanced high-technical design | |

| Competitive price, which has the most valuable | |

| OEM service offered, to meet the customers requirements | |

| Application | gearbox,auto,reduction box,engine machinery,mining machinery,bicycles,etc |

| Bearing Package | Pallet,wooden case,commercial packaging or as customers requirement |

| Packaging & Delivery: | ||||

| Selling Units: | Single item | |||

| Single package size: | 18X18X15 cm | |||

| Single gross weight: | 3.000 kg | |||

| Package Type: | A. Plastic tubes Pack + Carton + Wooden Pallet | |||

| B. Roll Pack + Carton + Wooden Pallet | ||||

| C. Individual Box +Plastic bag+ Carton + Wooden Pallet | ||||

| Lead Time : | ||||

| Quantity(Pieces) | 1 – 5000 | >5000 | ||

| Est. Time(days) | 7 | To be negotiated | ||

The nearly port: Tianjin or Qingdao

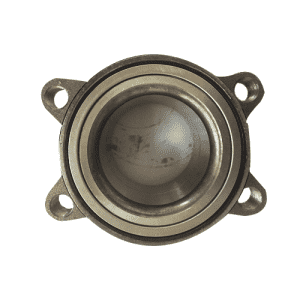

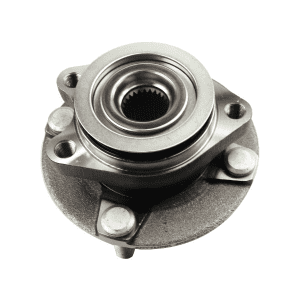

1) Wheel Hub Bearing Unit Kit Assembly Introduction:

The main function of wheel hub bearing is to bear load and provides accurate guidance for the hub rotation. It is a very important part which can bear both the radial load and axial load. The traditional bearing for car wheel hub is composed by two set of conical roller bearing. The installation, greasing, sealing and adjustment of play are all done in the car production line.

2) About Wheel Hub Bearing Unit considerations:

For the hub bearing unit, do not attempt to disassemble the hub bearing or adjust the seal of the hub unit, otherwise the seal will be damaged and water or dust will enter. Even the raceways of the seal ring and the inner ring are damaged, resulting in permanent failure of the bearing.

3) Wheel Hub Bearing Precautions:

The hub bearing unit is developed on the basis of standard angular contact ball bearings and tapered roller bearings. It integrates two sets of bearings and has good assembly performance, can eliminate clearance adjustment, light weight, compact structure and load capacity. Large, sealed bearings can be pre-loaded with grease, omitting external hub seals and maintenance-free. They have been widely used in cars, and there is a tendency to gradually expand applications in trucks.

*Advantage

SOLUTION

– At the beginning, we will have a communication with our customers on their demand, then our engineers will work out an optimum solution based on the customers’ demand and condition.

QUALITY CONTROL (Q/C)

- In accordance with ISO standards, we have professional Q/C staff, precision testing instruments and internal inspection system, the quality control is implemented in every process from material receiving to products packaging to ensure our bearings quality.

PACKAGE

– Standardized export packing and environment-protected packing material are used for our bearings, the custom boxes, labels, barcodes etc. can also be provided according to our customer’s request.

LOGISTIC

– Normally, our bearings will be sent to the customers by ocean transportation due to its heavy weight, airfreight, express is also available if our customers need.

WARRANTY

– We warrant our bearings to be free from defects in material and workmanship for a 12 months period from the shipping date, this warranty is voided by non-recommended use, improper installation or physical damage.

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top