Forklift gantry roller bearing / Lifting machine bearing / Roller bearing / Sheave bearing45*164*74

*Specifications

|

Bearing Detail |

||

| Item No. |

|

|

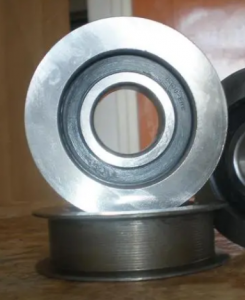

| Bearing Type | Forklift bearing | |

| Material | Chrome steel GCr15 | |

| Precision | P0,P2,P5,P6,P4 | |

| Clearance | C0,C2,C3,C4,C5 | |

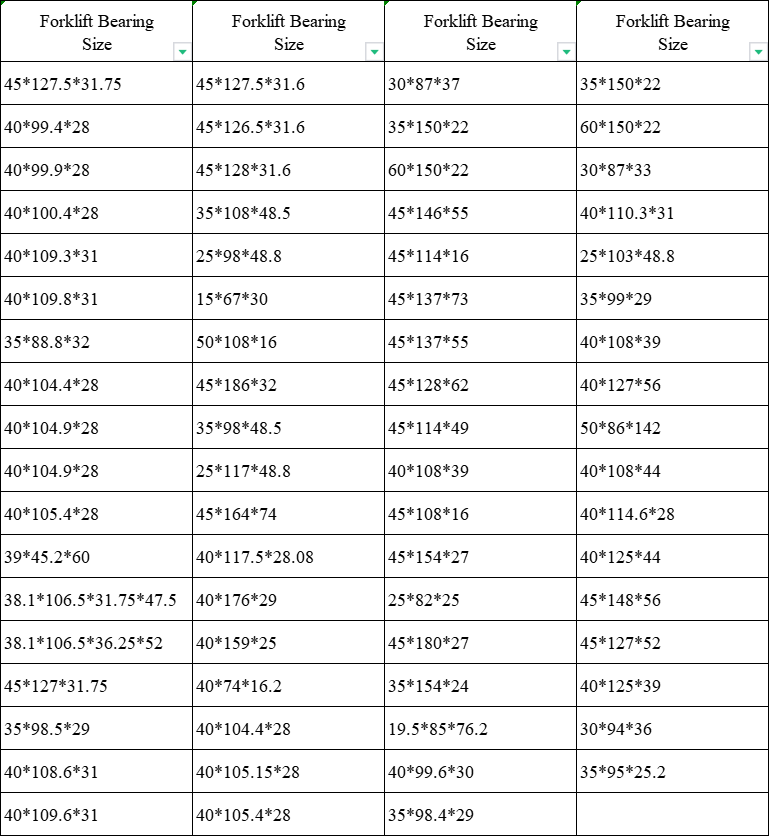

| Bearing size | inner diameter 0-200mm, outer diameter 0-400mm | |

| Cage type | Brass, steel, nylon, etc. | |

| Ball Bearings Feature | Long-life with high quality | |

| Low-noise with strict controlling the quality of JITO bearing | ||

| High-load by the advanced high-technical design | ||

| Competitive price, which has the most valuable | ||

| OEM service offered, to meet the customers requirements | ||

| Application | Automobiles,A very important hardware part on a forklift truck | |

| Bearing Package | Pallet,wooden case,commercial packaging or as customers’ requirement | |

| Packaging & Delivery: | ||||

| Packaging Details | Standard exporting packing or according to the customer’s requirements | |||

| Package Type: | A. Plastic tubes Pack + Carton + Wooden Pallet | |||

| B. Roll Pack + Carton + Wooden Pallet | ||||

| C. Individual Box +Plastic bag+ Carton + Wooden Pallet | ||||

| Lead Time : | ||||

| Quantity(Pieces) | 1 – 500 | >500 | ||

| Est. Time(days) | 2 | To be negotiated | ||

Type Of Bearing In Forklift Fittings

Forklift bearing is a very important hardware parts used in forklift trucks. Forklift bearing plays an irreplaceable role in the work of forklift trucks

Type of bearing in forklift fittings.

Forklift front axle chassis: hub bearing – angular contact ball bearing or deep groove ball bearing, tapered roller bearing, bearing for suspension – thrust ball bearing, thrust needle roller bearing, bearing for steering gear.

Forklift engine system: tensioning wheel, idler bearing – ball bearing with seat, deep groove ball bearing, tapered roller bearing, clutch separation bearing – ball bearing, water pump bearing – double row roller bearing and so on.

Forklift transmission system: needle roller bearing, tapered roller bearing.

Other parts (body, door frame) : door frame bearing, side roller bearing, etc.

Forklift Bearing Application

Forklift bearing is different from ordinary bearings, which are better than ordinary bearings in workmanship, bearing materials and performance. Industrial handling vehicles are widely used in ports, stations, airports, freight yards, factory workshops, warehouses, circulation centers and distribution centers, and can enter the cabin, carriages and containers for pallet cargo loading and unloading, handling operations. It is an essential equipment for pallet transportation and container transportation. Forklift plays a very important role in the logistics system of enterprises. It is the main force in the material handling equipment. Widely used in stations, ports, airports, factories, warehouses and other sectors of the national economy, is mechanized loading and unloading, stacking and short distance transportation of efficient equipment.

If more, please click our website www.jito.cc

*Advantage

SOLUTION

– At the beginning, we will have a communication with our customers on their demand, then our engineers will work out an optimum solution based on the customers’ demand and condition.

QUALITY CONTROL (Q/C)

- In accordance with ISO standards, we have professional Q/C staff, precision testing instruments and internal inspection system, the quality control is implemented in every process from material receiving to products packaging to ensure our bearings quality.

PACKAGE

– Standardized export packing and environment-protected packing material are used for our bearings, the custom boxes, labels, barcodes etc. can also be provided according to our customer’s request

LOGISTIC

– Normally, our bearings will be sent to the customers by ocean transportation due to its heavy weight, airfreight, express is also available if our customers need.

WARRANTY

– We warrant our bearings to be free from defects in material and workmanship for a 12 months period from the shipping date, this warranty is voided by non-recommended use, improper installation or physical damage.

*FAQ

Q: What’s your after-sales service and warranty?

A: We promise to bear the following responsibility when defective product is found:

1.12 months warranty from the first day of receiving goods;

2.Replacements would be sent with goods of your next order;

3.Refund for defective products if customers require.

Q: Do you accept ODM&OEM orders?

A: Yes, we provide ODM&OEM services to worldwide customers, we are able to customize housings in different styles, and sizes in different brands, we also customize circuit board & packaging box as per your requirements.

Q: What’s the MOQ?

A: MOQ is 500pcs for standardized products; for customized products, MOQ should be negotiated in advance. There is no MOQ for sample orders.

Q: How long is the lead time?

A: The lead time for sample orders is 3-5 days, for bulk orders is 5-15 days.

Q: How to place orders?

A: 1. Email us the model, brand and quantity, consignee information, shipping way and payment terms;

2.Proforma Invoice made and sent to you;

3.Complete Payment after confirming the PI;

4.Confirm Payment and arrange production.

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top